No matter how much forethought goes into a design, it’s often only when it’s in use that issues arise.

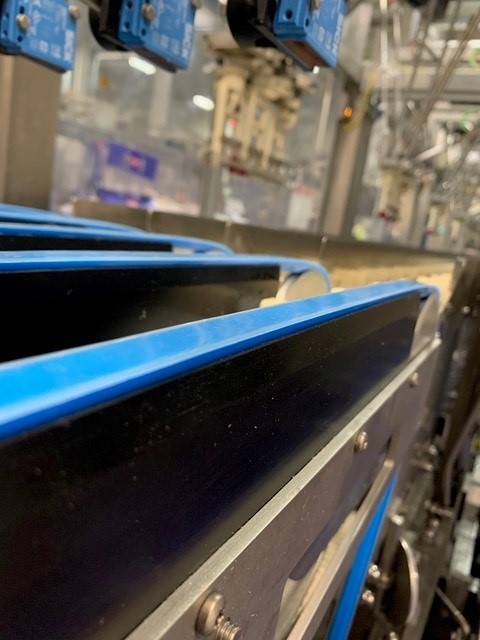

Our client called us in to discuss an ongoing problem with their conveyor belting system. The V guide was just slightly mis-sized, resulting in some product dropping off the guide throughout the day and clogging the transfer process. After 12 months, this was causing enough of an issue that they wanted a solution.

The body of the V guide section itself was the right size, but the top width needed increasing by just 1.5mm – a minor amount of clearance for such a big impact on a busy business.

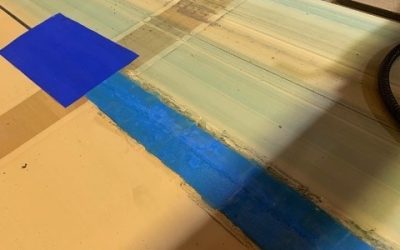

We decided that the best supplier in this instance was BEHAbelt, a truly innovative belting company in Europe that we have worked with for a long time. We provided our design adjustment to BEHA, and two weeks later they provided us with the replacement parts to fit.

The result – BEHA were able to provide the replacement parts to our exact specifications, as well as overcoming a problem with bonding the belt to the top of the guide. Once we had them we were able to install the parts in minutes, and resolve the issue on the first attempt – no more clogging or lost product for the client.

0 Comments